Screw press

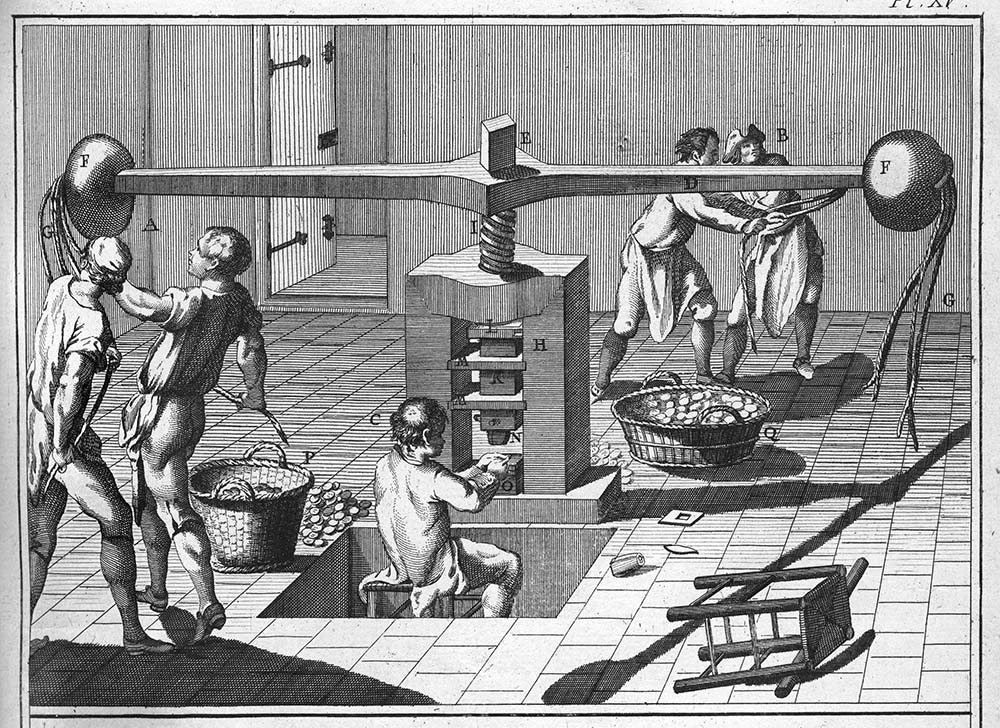

Towards the end of 1661, Thomas Simon was sent to France to bring back the engineer Pierre Blondeau to enable the mechanisation of coinage production. Blondeau supervised the new machinery, but it was still labour intensive. A team of six horses powered the rolling mills – four to operate them and two to provide for rest rotation. Furthermore, the screw presses required strenuous manual effort, seven men being assigned to a press, of whom three rested whilst four operated the press in twenty-minute spells. Production rates were rapid given the advances in technology, and coins were struck roughly at a rate of 30 a minute.

Blanks were added to the press by a young moneyer seated at eye level with the dies, and he would be responsible for flicking the finished coin away with his middle finger whilst using his thumb and index finger to add a fresh blank. A collision of the dies with nothing between them would have been incredibly wasteful of both money and time, and the position was a perilous one with a serious risk to the moneyer’s fingers.